3 & 5 Axis CNC Machining

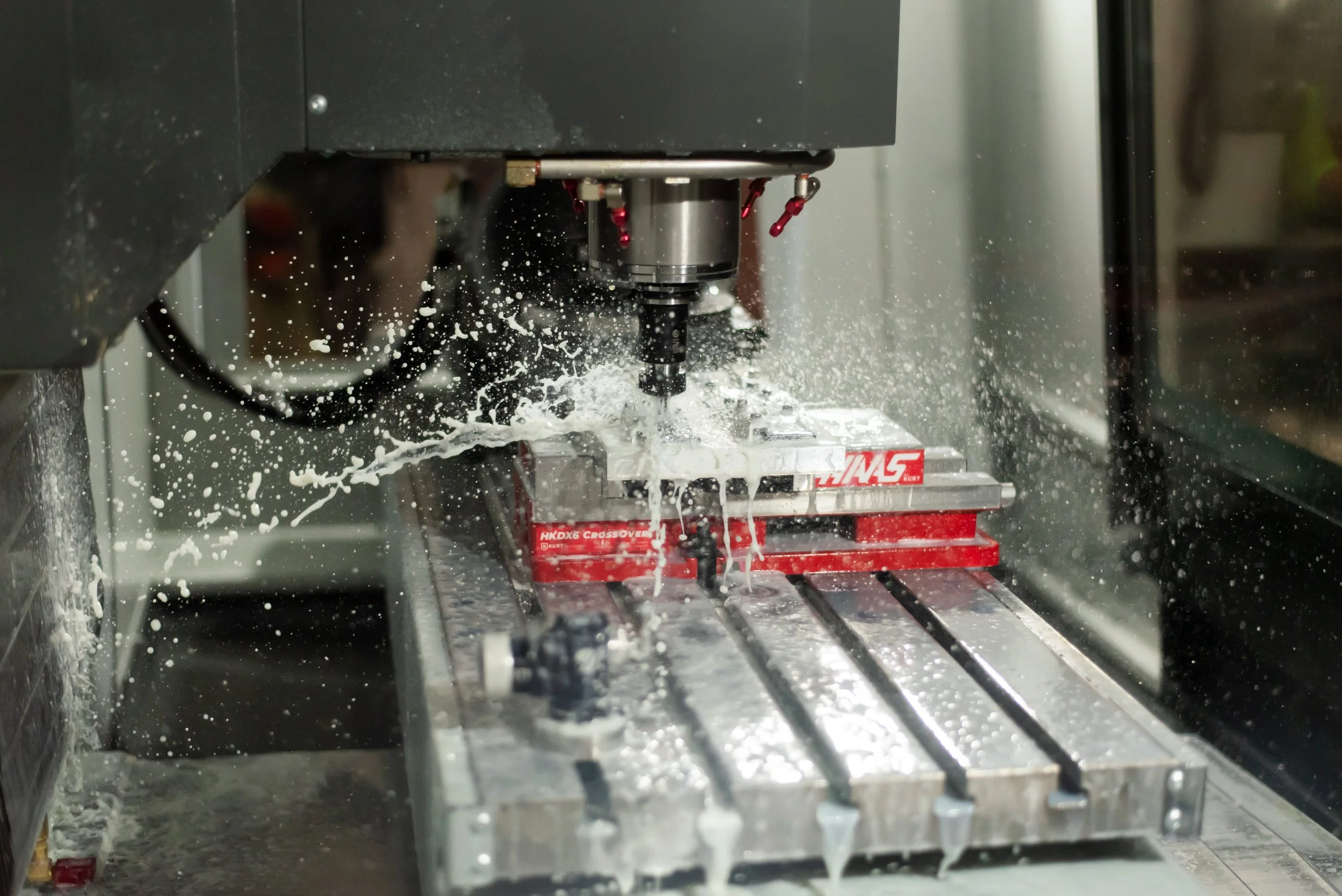

Precision 3 & 5 Axis CNC Machining for Complex Industrial Part

Advanced CNC milling for complex geometries, tight tolerances, and mission-critical applications.

Culmination Machine Works offers full-service CNC machining using advanced 3-axis and 5-axis equipment designed to handle even the most complex parts with precision and repeatability. From one-off components to short production runs, our Anchorage-based machine shop serves Alaska’s heavy industries with reliable, high-accuracy machining.

We specialize in close-tolerance parts used in oil & gas infrastructure, marine propulsion systems, aerospace assemblies, and custom mechanical systems.

3-Axis CNC Machining

Ideal for high-accuracy milling, drilling, and contouring of flat or prismatic parts.

Precise planar cuts and hole patterns

Efficient for small-batch production

Suitable for most general-purpose components

5-Axis CNC Machining

Provides the ability to machine complex geometries and multi-surface parts in a single setup.

Faster cycle times

Higher dimensional accuracy

Enables curved or compound surface machining

Reduces the need for manual repositioning or fixtures

Additional Capabilities

Milling and turning

Slotting, threading, and facing

Surface finishing and chamfering

Integrated laser cutting when applicable

Not sure if your file is ready for production?

Send it in for a flat-fee review. We’ll check compatibility, flag issues, and provide a quote if adjustments are needed.

Industrial and Commercial Parts and Repair

THE RIGHT MATERIALS

Faster Delivery & Accurate Results

Our team knows the right materials for the job is a critical component to successful production.

The right metal provides tight tolerances, every time. Complex geometries can be made more simply, which means shorter lead times, faster delivery, fewer steps, and ultimately, fewer mistakes.

-

2024, 6061, 7075

-

304, 316, 17-4 PH

-

N/A

-

A2, D2, H13, etc.

-

N/A

-

N/A

-

Delrin, UHMW, Nylon, PEEK

All materials are sourced and machined in-house to maintain quality and reduce delays.

Need advanced CNC machining?

Upload your drawings or tell us what you're building — we’ll deliver precision parts on schedule.